JoshDreamland

507

13

4

I started prototyping with styrofoam poster board, as this was easy to cut by hand using an exacto knife.

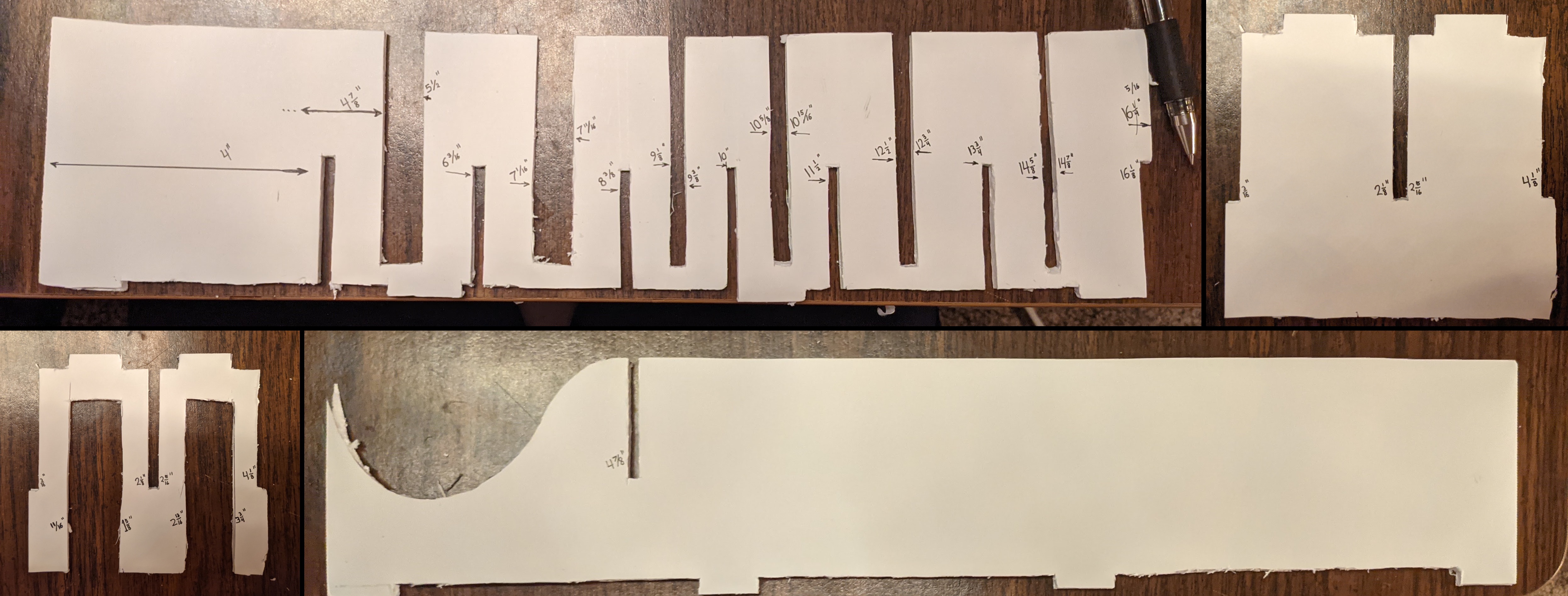

After the prototyping was done for that first corner, I took measurements.

The measurements allowed me to create a cut diagram for not just the existing parts, but the parts that were too intricate to do by hand.

I did up those intricate parts, as well as the horizontal supports, in some scrap plywood left over from other cuts. When I ran out of scrap plywood, I laser cut more foam board instead. Cutting foam board can be problematic, but I used an air filter pump and watched carefully for fires.

This is a view from the front.

Here you can see how the edges play together. There was a small problem with my vector that made the fit not quite perfect; I had to fix my drawing and cut the hole wider by hand.

And this is the very first prototype in action.

With the prototyping done, it was time to change materials. This time, I'd be redoing everything, rather than doing each piece one at a time on whatever scrap I had, trial-and-error style. Not shown in this gallery are several cuts that just didn't work. But here you can see all of the necessary components, packed as tightly as I could into my stock size.

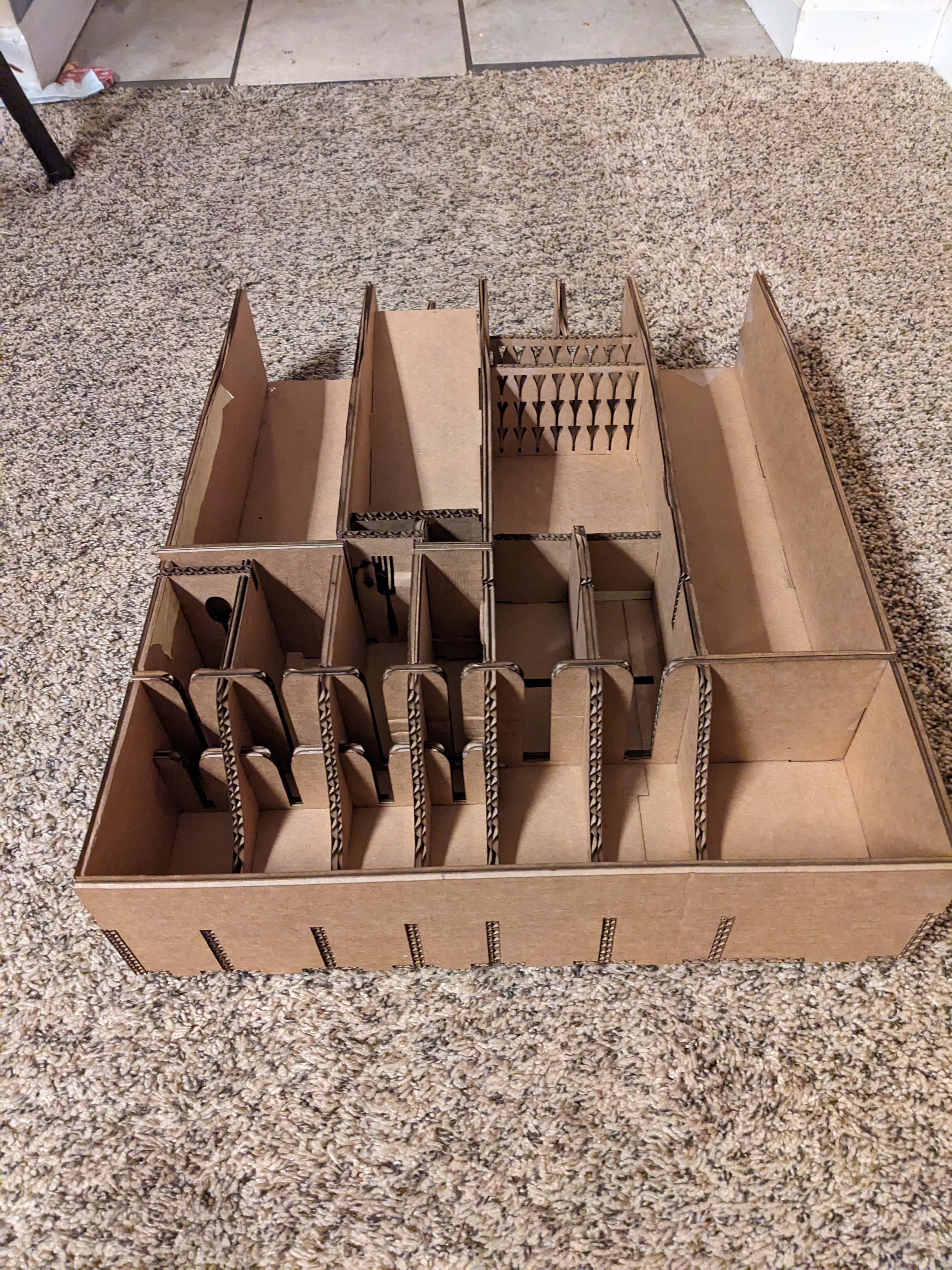

With the drawing fixed, I cut a brand new prototype, this time using some cardboard I had ordered earlier for this occasion.

The result was beautiful, and the fit was completely perfect. I was thrilled.

The knife holder functioned perfectly, even in cardboard.

Really, it was perfect; the only issue was that cardboard tends to not hold up well if you put the dishes away wet. Or drip anything on it.

But with the prototyping done, I could redo the cut in acrylic.

Cutting acrylic takes longer, but it's an all around better material for this application.

This cut had to share some of the base, as the base is larger than the cutter's working area...

The rest of the base took up most of a stock sheet on its own, leaving very little scrap.

But the final result was gorgeous. The only issue was, because I had to increase the laser exposure to cut through the acrylic as opposed to the cardboard, the result had a much, much looser fit... there are some things you just can't learn during prototyping.

Still, the result was everything I needed. Here it is, fully loaded.

While this tray isn't my proudest achievement, it was a really cool hobby project that took my drawer organization to the next level. I've been happily using this tray for years, now, and I almost wish more store-bought organizers were like this.

OrkenMork

In the 30 years of marriage, we've gone through 5 different sets of silverware...and none of thei were anything like the one it replaced...

Akivaran

WOW that looks so neat!

ufoara

that is one way to avoid the GridFinity trend.

JoshDreamland

It was actually a video someone I respect posted about their adoption of the GridFinity system that inspired me to post this today. I wanted to offer sympathy for that particular trap...

ufoara

Wonder if I saw the same video, Did his have off white with brown trim on his drawer dividers

JoshDreamland

He's gone fancy and done all the colors. I've been following the Marble Machine saga on YouTube, and this is one of the interesting rabbit holes the creator's gone down.