Grandolddrummer

6708

86

1

In my project post a few days ago, I was asked by a user in the comments to talk about my pegboard setup. It's been a lot of trial and error to get it to work how I wanted. So I'll pass on what I've learned to you folks and hopefully some of you find it useful.

In my very first shop, I had a 10' x 11' corner of a basement to work in (here's a picture I dug out of my phone https://i.imgur.com/vMTqdX3.jpg). My workbench had a set of shelves on either end and in between was a small bit of pegboard. So the tool storage was in a bit of a U shape (seen here: https://i.imgur.com/fxm8NHi.jpg). This is a layout that has persisted to this day. There's no real reason, just inertia, I suppose.

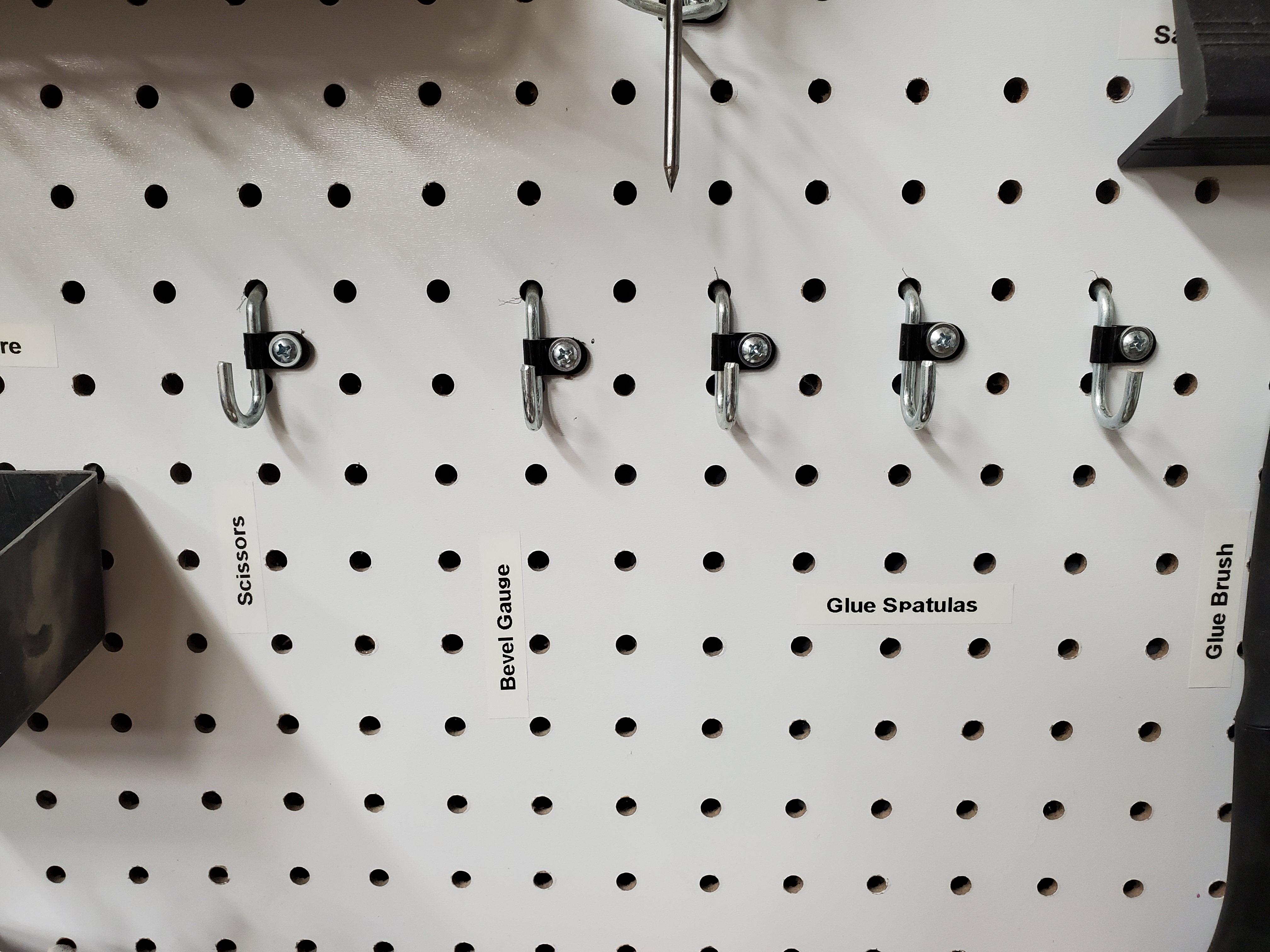

This is the secret sauce of the pegboard system. The biggest drawback to using pegboard is the propensity of the hooks to fall off behind the workbench every time you pull off a tool. The kits they sell with the peg hooks and holders come with these plastic bar things that are supposed to hold the hook in place. Those things are bullshit. They don't work and they limit how closely you can mount two hooks. Also, they allow no flexibility in hook angles. In the picture two up from here, you can see how the hooks holding the saws and the drafting triangle are mounted at an angle to give me easy access to grab the tool and put it away in a way that nests well and sits level.

These little guys will make your pegboard bulletproof. From the picture, you can see I'm not using them how I'm supposed to. They are 1/8" cable clamps usually used for running coaxial cable. But they are perfect for pegboard hooks. Here's a link to pick some up: https://www.amazon.com/dp/B0054RRX2W/ref=cm_sw_r_cp_apa_fabc_E.BXFb1KDDF0V?_encoding=UTF8&psc=1

All you need to attach the clamps is a 1/2" screw. These ones work great. I recommend using an 1/8" bit to drill a pilot hole. https://www.amazon.com/dp/B01MFAIS08/ref=cm_sw_r_cp_apa_fabc_R-BXFb2XR0DXP?_encoding=UTF8&psc=1

Another great thing about pegboard is it's not limited to the commercially available, metal hooks. You can make anything to hang whatever you need to.

The trick to doing that is sticking a couple of appropriately spaced L-hooks in the back and adding a chamfer on the top of the back so you can angle it into place.

Here's a few pictures to help you design something you need.

I also use pegboard to store most of my clamps. Similar to how the chisels were mounted, I just cut slots and added some L-hooks.

Hopefully this helps some of you with your shop organization.

Also, yes there is a BMW logo up there. I know they are not popular at all here on imgur. But, I first got into wrenching on cars by fixing up an old E46. I learned a lot about fixing cars by keeping that old car running. So, yeah I drive an old BMW, but I assure you I'm definitely not the guy who drives like an asshole.

Anyway, thanks for reading and have a nice day!

GunRack

Dude! I'm building a pegboard wall right now. Totally stealing these ideas

ThatOneFriendWhoTriesTooHard

There are few things sexier than a well organized peg board.

Eyhlix

Neat.

1nonlyS

Nice and smart

TheReaperSeesAll

Is this how Pegboard Nerds came to be

manderso7

I owned a 94 325i and learned a lot about what I could and couldn’t do on cars with that. Also, nice pegs.

FeChefImgur

"I assure you I'm definitely not the guy who drives like an asshole" - sounds exactly like what some who drives like an asshole would say...

FeChefImgur

Nice organisation though. The usage of the cable clamps to hold stuff where it's supposed to be is a great idea.

UnitConversionBot

10' ≈ 3 metres or 5.1 washing machines

UnitConversionBot

11' ≈ 3.35 metres

hessay12

So, you never use a turn signal.

Grandolddrummer

I use signals. I imagine whenever I use it, everyone else on the road is all

Makerofthingsmasherofstuff

Why do you have brass knuckles?

Grandolddrummer

Saw this video and wanted to make a set. https://youtu.be/iXKmL-UP9A4

FeChefImgur

That's what he uses if you don't put the tools back in the right place !

asmasm

This is amazing and the shot of the instruction book really adds a ton of detail. I have piles of discount peg board accessories in my 1/

asmasm

Garage that I've never got around to putting up. You run strips of 1 by along the studs and attach peg board to that? 2/2

Grandolddrummer

Oh. I forgot to mention that. I used strips of 1/2" plywood around the perimeter, screwed to studs and nailed the pegboard up to that.

asmasm

Interesting, the blogs say you need 1 by. 1/2" plywood is enough separation, that's awesome, I have a ton of that in scrap. This is great!

Grandolddrummer

I used 1/2" only because I had it on hand lol